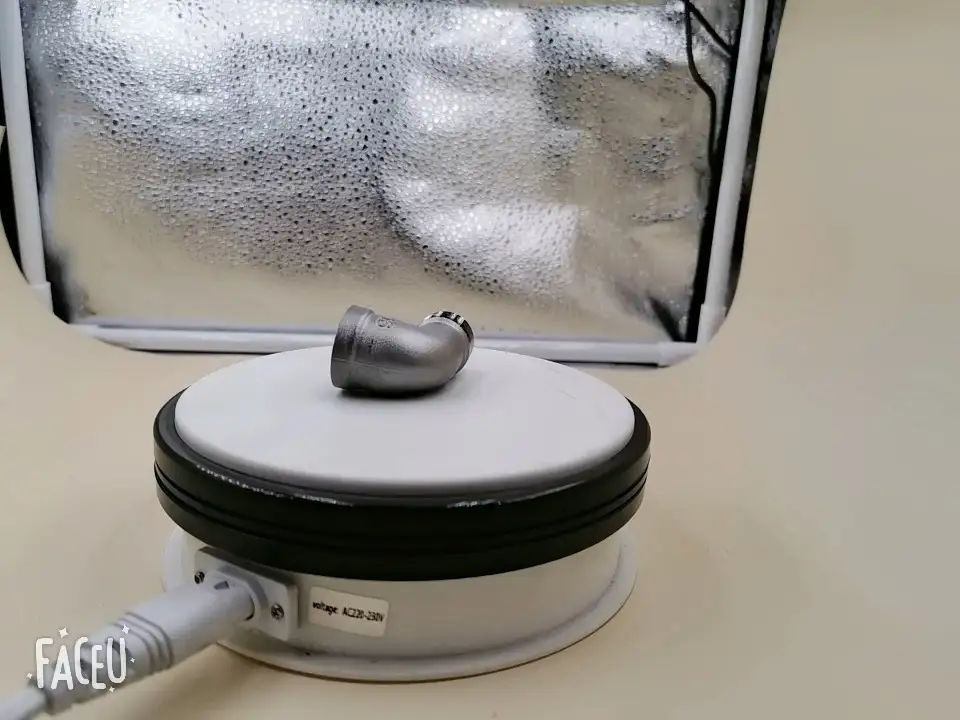

HY Stainless Steel ss 304 ss316 NPT BSPT BSPP Male Female Threaded 90 Degree Elbow

Product details

This stainless steel fitting from HY is a 90-degree elbow crafted from high-quality SS304 and SS316 stainless steel. It has a variety of key features, including NPT, BSPT, BSPP and other types of male and female thread design, this diverse selection of threads greatly enhances the compatibility with different standards of piping and fittings, and can be widely used in a variety of industrial piping systems, construction piping projects, and equipment connecting piping and other scenarios. Whether in the chemical, petroleum, pharmaceutical and other industries that require high material and connection accuracy, or ordinary civil building water supply and drainage systems, it can rely on its excellent stainless steel material performance, such as good corrosion resistance, high strength and stability, as well as accurate threaded connections, to ensure that the pipeline in the 90-degree turn to achieve a safe, reliable and efficient transmission of fluids or gases, and to prevent leakage and maintain long-term stable operation of the pipeline system, for the overall long-term stable operation of the pipeline system. This ensures safe, reliable and efficient transmission of fluid or gas at 90 degree turns, effectively prevents leakage and maintains the long-term stable operation of the piping system, providing a solid guarantee for the quality and performance of the overall project, making it a versatile and high-quality piping connection.

Product Overview

1. Material Advantages

● Strong corrosion resistance: SS304 and SS316 stainless steel material, with excellent corrosion resistance, can resist air, steam, water and other weak corrosive media as well as acid, alkali, salt and other chemical corrosive media corrosion, suitable for a variety of harsh working environments, such as chemical industry, marine, food processing and other fields, to effectively prolong the service life of the product.

● High strength and toughness: these two stainless steel materials have good strength and toughness, can withstand high pressure and impact, in the pipeline system can ensure long-term stable operation, not easy to deformation, rupture and other problems, improve the safety and reliability of the pipeline system.

2. Thread design advantages

● Multiple thread options: Equipped with NPT, BSPT, BSPP and other types of male and female threads, it can be connected with pipes and fittings of different standards, with strong compatibility, meeting the installation needs of various piping systems at home and abroad, and expanding the scope of application of the product.

● Tight and reliable connection: with high precision thread processing and smooth surface, it can form a tight sealing connection when connecting with matching pipes or pipe fittings, effectively preventing fluid or gas leakage and ensuring the sealing of piping system.

3. Structural design advantages

● Flexible 90-degree steering: 90-degree elbow design can realize the right-angle steering of the pipeline, which has strong flexibility in pipeline layout, and can carry out reasonable pipeline arrangement according to the actual engineering needs and optimize the space utilization of the pipeline system.

● Reduced fluid resistance: the internal structure is reasonably designed to reduce fluid resistance at the pipeline steering, making fluid or gas transmission in the pipeline smoother and improving the transmission efficiency of the pipeline system.

4. Brand and Quality Advantages

● Good brand reputation: HY, as a famous brand, has high visibility and good reputation in the market, and its product quality and after-sales service have been recognized by users, so choosing products of this brand can make users feel more at ease.

● Strict quality control: products in the production process in strict accordance with high standards of quality control, from raw material procurement to processing and manufacturing to finished product inspection, each link is strictly controlled to ensure that the product quality is stable and reliable, in line with relevant industry standards and norms.

Main Parts

| SIZE(INCH) | D1(MM) | D2(MM) | D3(MM) | A(MM) | B(MM) | C(MM) | D(MM) |

| 1/8” | 13.9 | 8 | 10.2 | 17 | 24 | 5.5 | 7 |

| 1/4” | 16.9 | 10.7 | 13.5 | 20 | 28 | 6.5 | 10 |

| 3/8” | 20.2 | 14.2 | 17.2 | 23 | 32 | 7 | 10 |

| 1/2” | 26.9 | 17.8 | 21 | 28 | 37 | 7 | 13 |

| 3/4” | 31.9 | 22.8 | 26.6 | 32 | 43 | 8 | 15 |

| 1" | 39.9 | 28.7 | 33.6 | 38 | 52 | 10 | 17 |

| 1-1/4” | 48.9 | 37.3 | 42.4 | 43 | 59 | 11 | 19 |

| 1-1/2” | 55.4 | 43.8 | 48.4 | 48 | 64 | 12 | 19 |

| 2" | 67.4 | 55.3 | 60.3 | 57 | 74 | 13 | 24 |

FAQ