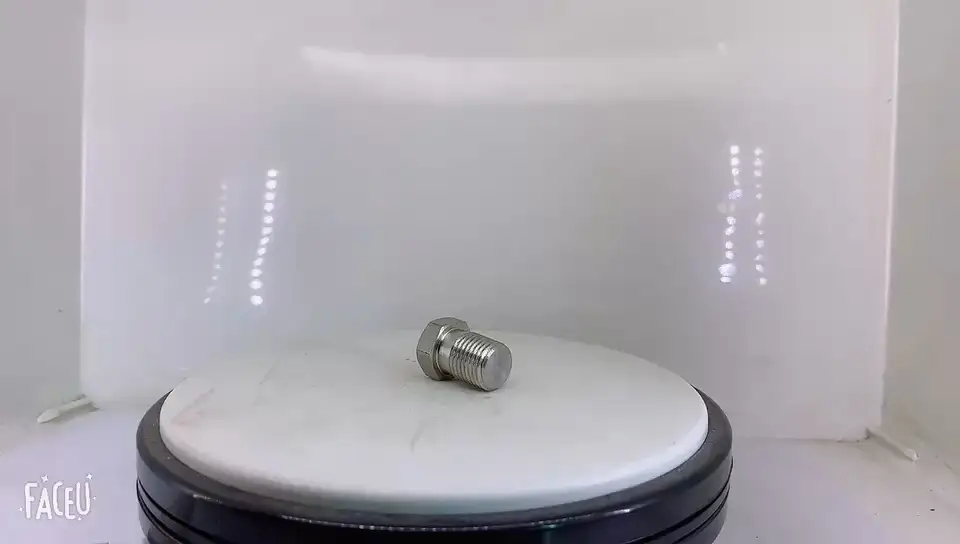

HY Male Bsp High Pressure Stainless Steel Pipe Thread Plug

Product details

Product Overview

HY Male Bsp High Pressure Stainless Steel Pipe Thread Plug is a key sealing component designed for high-pressure pipeline systems. It is carefully made of high-quality stainless steel and is suitable for a variety of harsh industrial environments, especially those that require extremely high pressure bearing capacity, corrosion resistance and sealing reliability.

The design of this threaded plug follows the British Standard Pipe Thread (BSP) specification to ensure precise matching with pipes and fittings of corresponding specifications. Its Male (external thread) design allows it to be easily screwed and installed with the matching internal threaded parts during pipeline connection and sealing operations, providing strong protection for the integrity of the pipeline system. Whether in high-pressure pipeline lines in petrochemical, natural gas transportation, offshore drilling platforms, or power, pharmaceutical and other industries, it can play a key role in effectively preventing media leakage and maintaining stable system operation.

Advantages and features

1. Excellent high-pressure resistance:

With its precise manufacturing process and high-strength stainless steel material, the threaded plug can withstand extremely high internal pressure. After rigorous testing, it can still maintain structural integrity under pressure conditions far exceeding conventional working conditions, ensuring that the pipeline system has no risk of leakage, providing solid support for high-pressure operations.

2. Super corrosion resistance:

The selection of high-quality stainless steel, rich in corrosion-resistant alloy elements such as nickel and chromium, gives it excellent corrosion resistance. Whether facing corrosive media such as acid and alkaline, or in harsh environments such as humidity and salt spray, it can maintain good physical properties for a long time, effectively extend the service life of the product, and reduce maintenance costs.

3. Accurate thread matching:

The threads are processed strictly in accordance with BSP standards, and the parameters such as pitch and tooth angle are accurate, ensuring tight screwing with the same standard pipe fittings. This precise matching not only improves installation efficiency and reduces jamming and misalignment during installation, but also maximizes the sealing effect and prevents medium leakage.

4. Reliable sealing performance:

The thread surface is finely processed, combined with high-quality sealing materials (such as polytetrafluoroethylene, etc.) or special sealing structure design, so that the threaded plug can form a tight sealing barrier after tightening. Even in the frequent pressure fluctuations and vibration environment of the pipeline system, it can continue to maintain a sealed state to ensure the safety and stability of medium transmission.

5. Durable materials and processes:

Stainless steel itself has good mechanical strength and toughness, coupled with advanced processing technology, such as cold forging, precision turning, etc., so that the product surface is smooth and the internal structure is dense, further improving its overall performance. This durable feature ensures that the product is not prone to wear, deformation and other problems during long-term use, providing strong support for the continuity of industrial production.

Dimension

Manufacture according to ASME Bl6.11

| Nominal Pipe size (inch) | Length Thread A | Hex Head Plug | |

| Width of Flat | Hex Height | ||

| S | H | ||

| 1/8" | 9.5 | 11.0 | 6 |

| 1/4" | 11.0 | 16.0 | 6 |

| 3/8" | 12.5 | 17.5 | 8 |

| 1/2" | 14.5 | 22.0 | 8 |

| 3/4" | 16.0 | 27.0 | 10 |

| 1" | 19.0 | 35.0 | 10 |

| 1-1/4" | 20.5 | 44.5 | 14 |

| 1-1/2" | 20.5 | 51.0 | 16 |

| 2" | 22.0 | 63.5 | 17 |

| 2-1/2" | 27.0 | 76.0 | 19 |

| 3" | 28.5 | 89.0 | 21 |

| 4" | 32.0 | 117.5 | 25 |

CENERAL NOTES:

(a)Dimenslons are in millimeters

FAQ