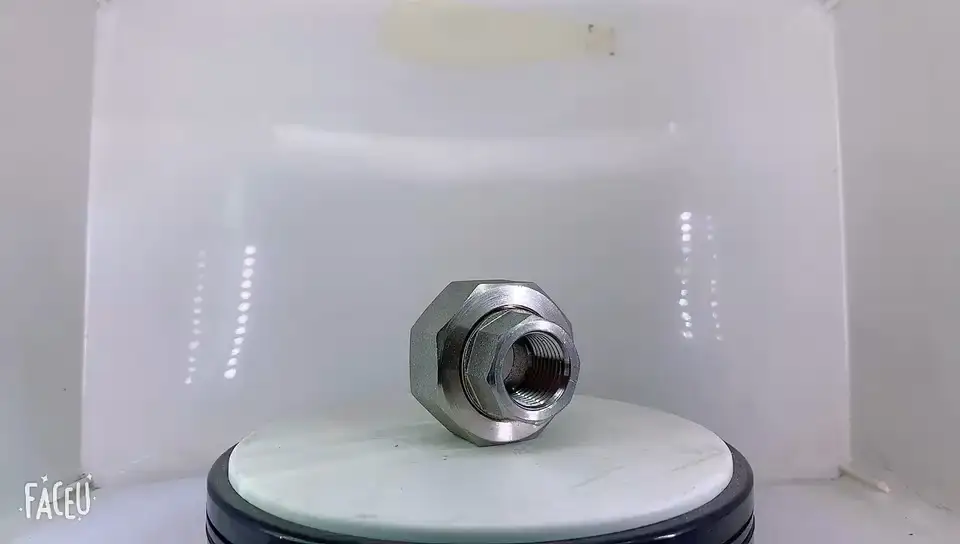

HY Class 3000 NPT Thread Stainless Steel Female Threaded Union

Product details

Product Overview

HY brand Class 3000 NPT threaded stainless steel internal threaded union is a high-quality pipe connection fitting. Made of high-quality stainless steel, it has excellent corrosion resistance and can ensure the stability and durability of the pipeline system in various harsh environments. It complies with the Class 3000 pressure rating standard and can withstand pressures up to 3000 pounds, suitable for high-pressure conditions. The NPT thread design ensures a tight and reliable connection and effectively prevents leakage. The internal thread structure is easy to install and disassemble, which greatly facilitates the maintenance and repair of pipelines. It is widely used in high-pressure pipeline connections in industrial fields such as petroleum, chemical, natural gas, and electric power. It provides a safe, efficient and convenient connection solution for complex pipeline systems and is an indispensable key component in high-pressure pipeline projects.

Product Advantages

1. High pressure adaptability: It complies with the Class 3000 pressure rating standard and can withstand pressures up to 3000 pounds. In high-pressure operating environments such as petroleum and chemical industries, it ensures stable pipeline connections without leakage risks, ensuring safe and stable operation of industrial processes.

2. High-quality stainless steel material: High-quality stainless steel is selected, which has excellent corrosion resistance and can resist erosion by harsh working conditions such as acid, alkali, moisture, and salt spray, extending product life and reducing maintenance costs. It is especially suitable for pipeline systems in the fields of chemical industry and marine engineering.

3. NPT thread precision connection: The NPT thread design ensures a tight and precise connection between the joint and the pipeline, effectively preventing medium leakage, ensuring the sealing of the pipeline system, improving transportation efficiency, and reducing resource waste and safety hazards caused by leakage.

4. Convenient operation of internal thread: The internal thread structure is easy to install and disassemble. During the maintenance, repair and modification of the pipeline system, the operation can be completed quickly without complex tools and professional skills, saving time and labor costs, and improving work efficiency.

Main Parts

| NPS(DN) | Outside Diameter | Wall Thickness | Water Way | Nominal Assembly Length | |

| A (mm) | B (in) | D1 (min) | C (min) | D | L |

| 6 | 1/8" | 14.7 | 2.5 | 6.43 | 41.4 |

| 8 | 1/4" | 19.0 | 3.1 | 9.45 | 41.4 |

| 10 | 3/8" | 22.9 | 3.2 | 13.51 | 46.0 |

| 15 | 1/2" | 27.7 | 3.8 | 17.07 | 49.0 |

| 20 | 3/4" | 33.5 | 4.0 | 21.39 | 56.9 |

| 25 | 1" | 41.4 | 4.6 | 27.74 | 62.0 |

| 32 | 1-1/4" | 50.5 | 4.9 | 35.36 | 71.1 |

| 40 | 1-1/2" | 57.2 | 5.1 | 41.20 | 76.5 |

| 50 | 2" | 70.1 | 5.6 | 52.12 | 86.1 |

| 65 | 2-1/2" | 85.3 | 7.1 | 64.31 | 102.4 |

| 80 | 3" | 102.4 | 7.7 | 77.27 | 109.0 |

GENERAL NOTES:

(a)Dimensions are in millimeters

FAQ