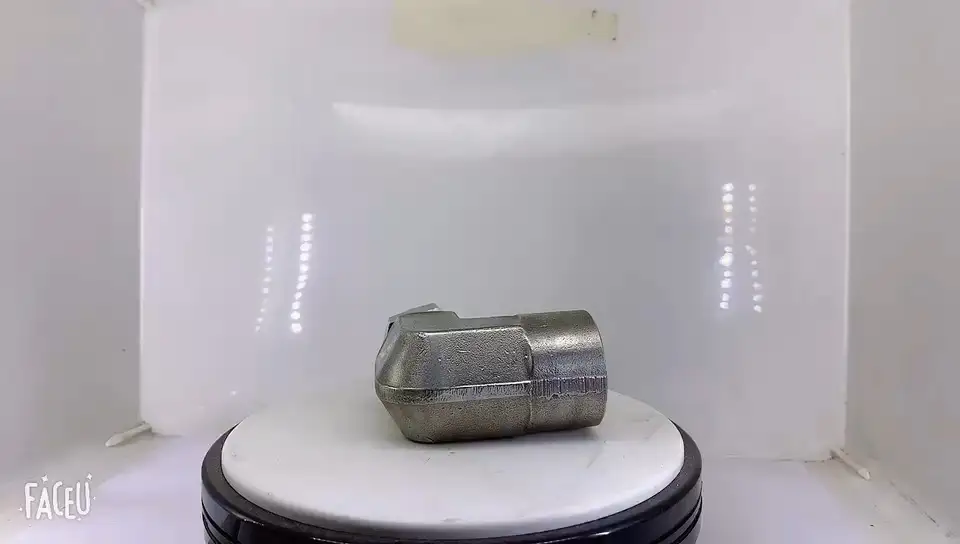

HY 6000 PSI 90 Degree Female Thread Compression Stainless Steel Elbow

Product details

HY This 90 degree stainless steel elbow features a female compression design with excellent pressure resistance up to 6000 PSI. Made of high quality stainless steel, this elbow is widely used in high pressure piping systems such as petrochemical and high pressure gas transportation. The precise 90-degree angle design ensures an effective change of pipe flow direction, and the female compression connection not only facilitates installation and disassembly, but also provides a reliable seal to ensure the safe and stable transmission of high-pressure fluids in the pipeline, which effectively reduces the risk of leakage and prolongs the service life of piping systems.

Product Overview

1. Excellent pressure resistance:

●Capable of withstanding ultra-high pressure up to 6000 PSI, it performs well in high-pressure pipeline operation scenarios. Whether it is high-pressure liquid or gas transmission, it can ensure the safe and stable operation of pipeline system, effectively reduce the risk of leakage and rupture caused by excessive pressure, and provide a solid guarantee for the continuity of industrial production.

2. High quality and durable material:

● The use of stainless steel, with excellent corrosion resistance, can resist the erosion of a variety of harsh environmental factors, including moisture, acid and alkali environment. This not only extends the service life of the elbow itself, reduces the cost and trouble of frequent replacement, but also ensures the reliability and stability of the entire piping system in long-term operation, especially for chemical, marine and other industries with high corrosion requirements for the material.

3. Accurate 90-degree design:

● Its precise 90-degree angle design can accurately change the flow direction of the pipeline, which can realize efficient and orderly fluid transmission path planning in complex pipeline layouts. This precision helps to reduce the resistance and turbulence of the fluid in the steering process, improve the efficiency of fluid transportation, reduce energy consumption, and at the same time, it is also conducive to the compact installation of the entire piping system and aesthetic layout.

4. Advantage of female compression connection:

●Female thread compression connection is easy to operate, no special complicated tools and professional skills are needed for installation and disassembly, which is convenient for piping system maintenance, overhaul and renovation. Moreover, this type of connection can provide reliable sealing effect, effectively prevent fluid leakage, even under high pressure and long time operation conditions, still can maintain good sealing, reduce the waste of resources, environmental pollution and safety accidents caused by leakage.

5. Wide applicability:

● With its high pressure resistance, corrosion resistance and reliable connection characteristics, the stainless steel elbow can be widely used in high-pressure piping systems in many industries, such as oil extraction and refining, natural gas transmission, power engineering, pharmaceutical industry and so on. It can be well matched with different types and sizes of pipes, fittings and equipment, providing a flexible and reliable piping connection solution for diversified industrial projects.

Main Parts

| MODEL NUMBER | TUBE OD | NPT SIZE | DIMENSIONS (INCH) | |||

| T,INCH | A | D | E | F(INCH) | ||

| HY-FE-1/8-1/8 | 1/8 | 1/8 | 0.97 | 0.50 | 0.09 | 1/2 |

| HY-FE-1/8-1/4 | 1/4 | 1.08 | 11/16 | |||

| HY-FE-3/16-1/8 | 3/16 | 1/8 | 1.00 | 0.54 | 0.12 | 1/2 |

| HY-FE-1/4-1/8 | 1/4 | 1/8 | 1.06 | 0.60 | 0.19 | 1/2 |

| HY-FE-1/4-1/4 | 1/4 | 1.17 | 11/16 | |||

| HY-FE-1/4-3/8 | 3/8 | 1.25 | 11/16 | |||

| HY-FE-1/4-1/2 | 1/2 | 1.36 | 1 | |||

| HY-FE-5/16-1/8 | 5/16 | 1/8 | 1.13 | 0.64 | 0.25 | 9/16 |

| HY-FE-5/16-1/4 | 1/4 | 1.20 | 11/16 | |||

| HY-FE-3/8-1/8 | 3/8 | 1/8 | 1.20 | 0.66 | 0.28 | 5/8 |

| HY-FE-3/8-1/4 | 1/4 | 1.23 | 11/16 | |||

| HY-FE-3/8-3/8 | 3/8 | 1.31 | 13/16 | |||

| HY FE-3/8-1/2 | 1/2 | 1.42 | 1 | |||

| HY-FE-1/2-1/4 | 1/2 | 1/4 | 1.42 | 0.90 | 0.41 | 13/16 |

| HY-FE-1/2-3/8 | 3/8 | 1.42 | 13/16 | |||

| HY-FE-1/2-1/2 | 1/2 | 1.53 | 1 | |||

| HY-FE-5/8-3/8 | 5/8 | 3/8 | 1.50 | 0.96 | 0.50 | 15/16 |

| HY-FE-5/8-1/2 | 1/2 | 1.57 | 11/16 | |||

| HY-FE-3/4-1/2 | 3/4 | 1/2 | 1.57 | 0.96 | 0.62 | 11/16 |

| HY-FE-3/4-3/4 | 3/4 | 1.76 | 13/8 | |||

| HY-FE-7/8-3/4 | 7/8 | 3/4 | 1.76 | 1.02 | 0.72 | 13/8 |

| HY-FE-1-3/4 | 1 | 3/4 | 1.93 | 1.23 | 0.88 | 13/8 |

| HY-FE-1-1 | 1 | 2.11 | 1-11/16 | |||

| HY-FE-6-1/8 | 6 | 1/8 | 27.00 | 15.30 | 4.80 | 1/2 |

| HY-FE-6-1/4 | 1/4 | 29.80 | 11/16 | |||

| HY-FE-6-1/2 | 1/2 | 34.60 | 1 | |||

| HY-FE-8-1/4 | 8 | 1/4 | 30.60 | 16.20 | 6.40 | 11/16 |

| HY-FE-10-1/8 | 10 | 1/8 | 31.50 | 17.20 | 7.90 | 11/16 |

| HY-FE-10-1/4 | 1/4 | 33.50 | 13/16 | |||

| HY-FE-12-1/4 | 12 | 1/4 | 36.00 | 22.80 | 9.50 | 13/16 |

| HY-FE-12-1/2 | 1/2 | 38.80 | 1 | |||

| HY-FE-16-1/2 | 16 | 1/2 | 39.50 | 24.40 | 12.70 | 11/16 |

FAQ