Maximizing Precision: The Importance Of A High-Quality Needle Valve

When it comes to achieving optimal performance in fluid control systems, nothing is more crucial than using a high-quality needle valve. The precision and accuracy offered by a top-notch needle valve can make a significant difference in the efficiency and effectiveness of your system. In this article, we will explore the importance of maximizing precision with a high-quality needle valve and how it can benefit your industrial operations. Whether you are in the oil and gas industry, chemical processing, or any other sector that relies on precise fluid control, this article is a must-read for anyone looking to improve their system's performance.

- Understanding the Functionality of Needle Valves in Precision Instruments

In the world of precision instruments, accuracy is paramount. Whether it be in medical devices, laboratory equipment, or industrial machinery, the smallest error can have significant consequences. This is where the importance of a high-quality precision needle valve comes into play.

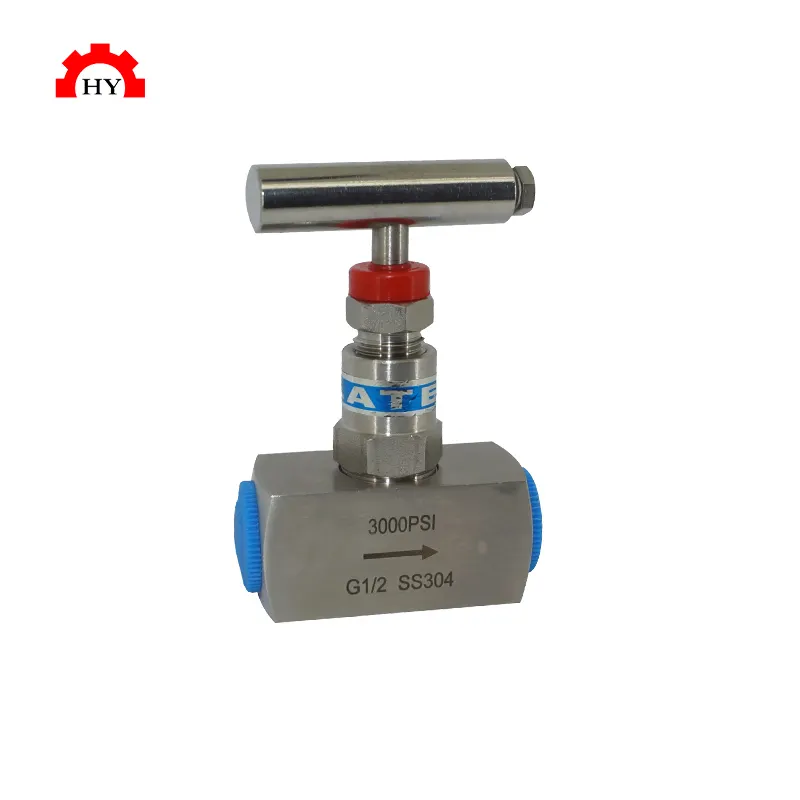

A needle valve is a type of valve with a small, tapered conical disc at the end of a threaded stem that fits into a matching seat. It is commonly used to control the flow of fluid in a system, allowing for precise regulation and fine adjustments. The functionality of needle valves is crucial in maintaining the accuracy and efficiency of precision instruments.

One of the key features of a precision needle valve is its ability to provide precise control over flow rate. The small, tapered disc allows for fine adjustments, making it ideal for applications where even the smallest variations in flow can have a significant impact. This level of control is essential in industries where precision is critical, such as in medical devices or scientific instruments.

In addition to precise control, a high-quality precision needle valve also offers excellent durability and reliability. The materials used in the construction of the valve are crucial in ensuring its longevity and performance. Stainless steel or brass are commonly used materials that provide resistance to corrosion and wear, ensuring the valve can withstand the harsh conditions often found in industrial settings.

Another important factor to consider when choosing a precision needle valve is the type of connection it offers. Whether it be compression, threaded, or flanged connections, the choice of connection can impact the ease of installation and maintenance of the valve. Additionally, the type of connection can also affect the overall performance and reliability of the valve in a given application.

Furthermore, the design of the precision needle valve plays a significant role in its functionality. Features such as the shape and size of the valve body, the type of seat and seal used, and the method of actuation all contribute to the overall performance of the valve. A well-designed needle valve will not only provide precise control over flow rate but also ensure minimal leakage and optimal efficiency.

In conclusion, the functionality of needle valves in precision instruments is paramount in maximizing accuracy and efficiency. A high-quality precision needle valve offers precise control, durability, and reliability, making it an essential component in industries where precision is critical. By understanding the importance of a high-quality needle valve and selecting the right valve for the application, manufacturers and end-users can ensure the optimal performance of their precision instruments.

- The Role of Material Quality in Ensuring Accuracy and Reliability

In industries where precision and accuracy are crucial, the quality of equipment is paramount. The use of high-quality needle valves plays a significant role in ensuring the accuracy and reliability of various systems and processes. The importance of material quality cannot be overstated when it comes to maximizing precision.

The keyword of this article, "precision needle valve", highlights the critical nature of these components in achieving precise control over the flow of fluids or gases in a system. Needle valves are commonly used in applications where fine adjustments in flow rate or pressure are required, such as in instrumentation, control systems, and research laboratories. The ability to finely tune the flow through a system is essential for achieving reliable and accurate results.

One of the key factors that determine the performance of a needle valve is the quality of materials used in its construction. High-quality materials such as stainless steel, brass, or titanium are preferred for their durability, resistance to corrosion, and ability to maintain tight shut-off capabilities over extended periods. Inferior materials can lead to leaks, inconsistent flow rates, and decreased overall reliability.

In addition to material quality, the design and manufacturing process of a precision needle valve also play a significant role in ensuring its accuracy and reliability. The tight tolerances and precision machining required to produce a high-quality valve contribute to its ability to provide precise control over flow rates and pressures. Well-designed needle valves will have minimal internal dead space, reducing the risk of fluid entrapment and contamination.

Proper installation and maintenance are also crucial to maximizing the precision of a needle valve. Regular inspections, cleaning, and calibration are necessary to ensure that the valve continues to operate at peak performance. Any signs of wear or deterioration should be addressed promptly to prevent potential leaks or malfunctions.

In conclusion, the role of material quality in ensuring the accuracy and reliability of a precision needle valve cannot be understated. High-quality materials, precision manufacturing, and proper maintenance are all essential factors in maximizing the performance of these critical components. Investing in a high-quality needle valve will not only ensure precise control over flow rates and pressures but also contribute to the overall efficiency and reliability of the systems in which they are used.

- Key Features to Look for in a High-Quality Needle Valve

When it comes to industries that require precise control over the flow of fluids or gases, the importance of a high-quality needle valve cannot be overstated. A needle valve is a type of valve that is used to regulate the flow rate of a fluid by gradually opening or closing a needle-shaped plunger within the valve body. This level of control is crucial in applications where even the slightest variation in flow rate can have a significant impact on the overall process.

One of the key features to look for in a high-quality precision needle valve is the construction material. Needle valves are available in a variety of materials, such as stainless steel, brass, and plastic. The choice of material will depend on the specific application and the type of fluid or gas being controlled. Stainless steel needle valves are ideal for high-pressure and high-temperature applications, while brass needle valves are more economical and suitable for lower pressure environments. Plastic needle valves are lightweight and corrosion-resistant, making them ideal for certain industrial and laboratory applications.

Another important feature to consider is the design of the valve. High-quality precision needle valves will have a smooth and precise operation, allowing for accurate control over the flow rate. The valve should also have a tight seal when closed to prevent any leaks or pressure loss. Additionally, the valve should be easy to adjust and operate, with clear markings for precise flow rate control.

Furthermore, the size of the needle valve is also an important factor to consider. The size of the valve will determine the maximum flow rate that can be achieved, as well as the pressure rating of the valve. It is important to select a needle valve that is appropriately sized for the specific application to ensure optimal performance.

In addition to the construction material, design, and size of the valve, it is also important to consider the brand and reputation of the manufacturer. High-quality precision needle valves are typically manufactured by well-established companies with a proven track record of producing reliable and durable products. It is important to do thorough research and read reviews from other customers before making a purchase to ensure that you are getting a high-quality needle valve that will meet your specific requirements.

In conclusion, when it comes to maximizing precision in fluid and gas flow control, a high-quality needle valve is essential. By paying attention to key features such as construction material, design, size, and manufacturer reputation, you can ensure that you are investing in a reliable and durable valve that will provide accurate flow rate control for your specific application. Remember, precision is key when it comes to needle valves, so do not compromise on quality when selecting a valve for your industrial or laboratory needs.

- Importance of Proper Installation and Maintenance for Optimal Performance

Needle valves are essential components in various industries, providing a precise and reliable method for controlling the flow of fluids and gases. Whether used in manufacturing processes, laboratory settings, or chemical applications, the proper installation and maintenance of a precision needle valve are crucial for optimal performance and accuracy. In this article, we will explore the importance of high-quality needle valves and the impact that proper installation and maintenance can have on their functionality.

A precision needle valve is designed to provide precise control over the flow rate of a fluid or gas, allowing for fine adjustments to be made with minimal effort. This level of precision is essential in situations where even the smallest variation in flow can have significant effects on the final outcome. For example, in a laboratory setting, a precise flow rate is necessary for conducting experiments and producing accurate results. In a manufacturing process, precise control over the flow of materials is crucial for ensuring product quality and consistency.

In order to achieve optimal performance, a high-quality needle valve must be properly installed and maintained. Improper installation can lead to leaks, malfunctions, and other issues that can compromise the valve's performance. Additionally, regular maintenance is necessary to ensure that the valve continues to operate smoothly and accurately over time.

Proper installation of a precision needle valve begins with selecting the right valve for the application. Factors such as the type of fluid or gas being controlled, the pressure and temperature conditions, and the flow rate requirements should all be considered when choosing a valve. Once the valve has been selected, it should be installed according to the manufacturer's instructions, taking care to properly align and secure all components.

Regular maintenance is essential for ensuring the long-term performance of a precision needle valve. This includes periodic inspections to check for any signs of wear or damage, as well as cleaning and lubricating the valve as needed. Any necessary repairs or replacements should be made promptly to prevent further damage and ensure continued reliability.

In conclusion, the importance of proper installation and maintenance for a high-quality precision needle valve cannot be overstated. By taking the time to select the right valve, install it correctly, and maintain it regularly, users can ensure that their valve will continue to provide accurate and reliable control over fluid and gas flow for years to come. Investing in a high-quality needle valve and following best practices for installation and maintenance is essential for maximizing precision and achieving optimal performance.

- Case Studies Demonstrating the Impact of Needle Valve Quality on Overall System Precision

Precision needle valves play a crucial role in various industrial and scientific applications where accuracy and control are paramount. In this article, we will explore the impact of needle valve quality on overall system precision through a series of case studies.

First and foremost, it is important to understand the significance of precision in industrial settings. Precision refers to the ability to control variables within a system to achieve consistent and accurate results. In many industries, such as pharmaceuticals, aerospace, and automotive, even the slightest deviation from the desired specifications can have serious consequences. This is where precision needle valves come into play.

A precision needle valve is a type of flow control valve that allows for precise regulation of flow rates. It is commonly used in applications where even minor adjustments can make a significant difference, such as in laboratory experiments, chemical processing, and instrumentation.

One of the key factors that determine the performance of a precision needle valve is its quality. Poor-quality needle valves can result in leaks, inconsistent flow rates, and unreliable performance, leading to decreased system precision. On the other hand, high-quality needle valves are designed to provide accurate and repeatable flow control, ensuring consistent results and optimal system performance.

To demonstrate the impact of needle valve quality on overall system precision, let us consider a few case studies:

Case Study 1: Pharmaceutical Manufacturing

In a pharmaceutical manufacturing facility, precision is critical to ensure the quality and efficacy of medications. A high-quality precision needle valve is used in the production process to control the flow of active ingredients with precision accuracy. If the needle valve were of poor quality, it could lead to variations in dosage, compromising the effectiveness of the medication.

Case Study 2: Environmental Testing

In environmental testing laboratories, precise control of flow rates is essential to accurately measure pollutants and contaminants in air and water samples. A precision needle valve of high quality ensures that the flow rates are consistent and reliable, enabling scientists to obtain accurate data for environmental monitoring and analysis.

Case Study 3: Aerospace Engineering

In aerospace engineering, precision is paramount to ensure the safety and reliability of aircraft components. A high-quality precision needle valve is used in fuel systems to regulate the flow of fuel with precision accuracy. Any deviations in flow rates could result in engine malfunctions or failures, highlighting the importance of using high-quality needle valves in aerospace applications.

In conclusion, the importance of a high-quality precision needle valve cannot be overstated. By investing in a quality needle valve, industries can achieve optimal system precision, leading to improved performance, accuracy, and reliability. Whether in pharmaceutical manufacturing, environmental testing, aerospace engineering, or any other industry where precision is critical, choosing the right needle valve can make a significant difference in overall system performance.

Conclusion

In conclusion, the importance of a high-quality needle valve cannot be overstated when it comes to maximizing precision in various industrial applications. From controlling flow rates to ensuring accurate measurements, a reliable needle valve is essential for achieving consistent and efficient operations. Investing in a top-notch needle valve is not only a smart business decision but also a vital step towards improving overall performance and productivity. By choosing a high-quality needle valve, businesses can minimize downtime, reduce maintenance costs, and ultimately, maximize their precision and efficiency. So, don't overlook the significance of a good needle valve - it may just be the key to unlocking your full potential in the industrial world.