Improving Efficiency With An Automatic Needle Valve

Understanding the Functionality of an Automatic Needle Valve

Benefits of Implementing an Automatic Needle Valve for Efficiency Improvement

In the modern industrial world, the quest for efficiency is a never-ending journey. As companies strive to streamline their processes and increase productivity, the adoption of automation technologies has become a key focus. One such technology that is gaining popularity in various industries is the automatic needle valve.

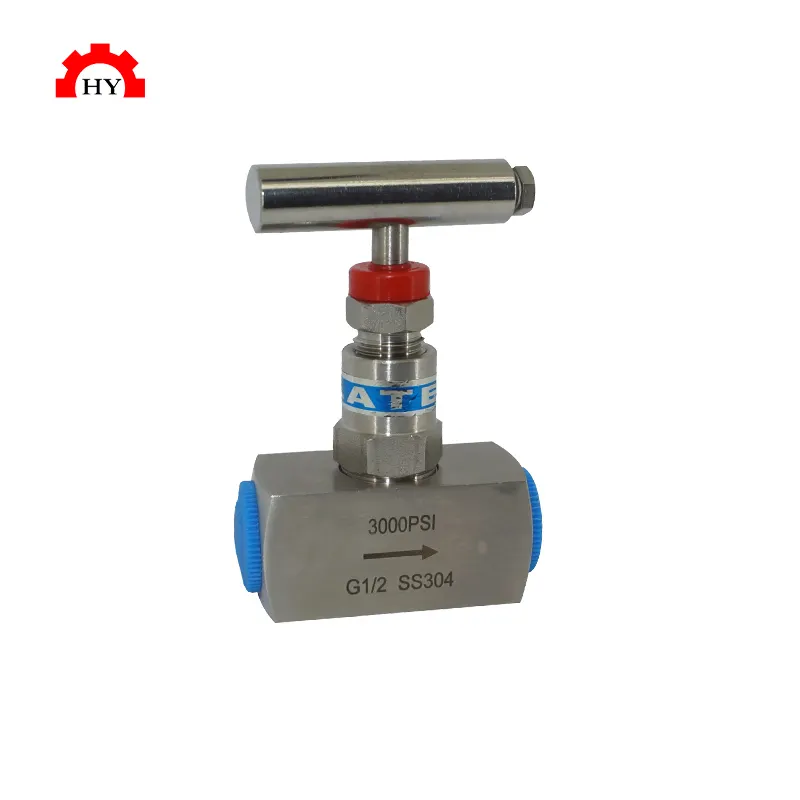

An automatic needle valve is a type of flow control valve that uses a tapered needle to regulate the flow of a fluid. Unlike manual needle valves that require constant adjustment by an operator, automatic needle valves can be programmed to maintain a desired flow rate without human intervention. This automation not only improves efficiency but also reduces the risk of human errors and variability in the process.

One of the primary benefits of implementing an automatic needle valve is the significant improvement in efficiency. By automating the flow control process, companies can achieve more precise and consistent results, leading to higher productivity and cost savings. The ability to program the valve to maintain a specific flow rate also eliminates the need for constant monitoring and adjustment, freeing up valuable time and resources for other tasks.

Another advantage of automatic needle valves is their versatility and adaptability. These valves can be easily integrated into existing systems and customized to meet specific requirements. Whether it is controlling the flow of gas, liquid, or steam, automatic needle valves can handle a wide range of applications with precision and accuracy. This flexibility makes them an ideal choice for industries such as manufacturing, pharmaceuticals, food and beverage, and oil and gas.

In addition to improving efficiency and productivity, automatic needle valves also offer safety benefits. By automating the flow control process, companies can reduce the risk of accidents and spills caused by human error. The precise and consistent flow regulation provided by automatic needle valves helps ensure the safe and reliable operation of equipment and processes, ultimately creating a safer work environment for employees.

Furthermore, the implementation of automatic needle valves can lead to long-term cost savings for companies. By reducing waste, optimizing processes, and minimizing downtime, automatic needle valves can help increase overall profitability. The initial investment in automation technology is often offset by the significant returns in terms of improved efficiency, reduced maintenance costs, and increased production output.

In conclusion, the benefits of implementing an automatic needle valve for efficiency improvement are undeniable. From increased productivity and cost savings to improved safety and versatility, automatic needle valves offer a wide range of advantages for companies looking to optimize their processes. As industries continue to embrace automation technologies, automatic needle valves are set to play a crucial role in driving efficiency and innovation in the years to come.

Factors to Consider When Choosing an Automatic Needle Valve

Installation and Setup of an Automatic Needle Valve for Optimum Performance

Improving Efficiency with an Automatic Needle Valve: Installation and Setup for Optimum Performance

Automatic needle valves are an essential component in various industrial processes, providing precise control over the flow of fluids or gases. These valves are designed to regulate the flow rate by adjusting the size of the needle that restricts the flow passage. When properly installed and set up, automatic needle valves can significantly improve efficiency, reduce waste, and enhance overall system performance.

Installation of an automatic needle valve is a critical step in ensuring its proper functioning. The first step is to choose the right valve for the application, considering factors such as size, materials, pressure ratings, and flow requirements. Once the appropriate valve is selected, it should be installed in line with the flow direction specified by the manufacturer.

Before installing the valve, it is essential to prepare the installation area by ensuring that it is clean, dry, and free from any debris or obstructions. The valve should be placed in a location that allows for easy access and maintenance, with sufficient clearance around it for operation. Proper alignment with the piping system is crucial to prevent leaks or obstructions in the flow path.

Once the valve is installed, the next step is to set it up for optimum performance. This involves adjusting the needle position to achieve the desired flow rate or pressure control. The valve should be gradually opened or closed to find the optimal setting that provides the required flow without causing excessive pressure drop or turbulence in the system.

In some cases, additional accessories such as positioners, controllers, or actuators may be required to automate the operation of the valve. These components can help to fine-tune the performance of the valve, improve response times, and maintain precise control over the flow rate. Proper calibration of these accessories is essential to ensure accurate and reliable operation of the valve.

Regular maintenance and inspection of the automatic needle valve are also crucial to ensure its continued efficiency and performance. This includes checking for leaks, corrosion, or wear and tear on the valve components. Any signs of damage or deterioration should be promptly addressed to prevent costly repairs or downtime in the system.

In conclusion, installing and setting up an automatic needle valve for optimum performance requires careful planning, proper installation, and regular maintenance. By following these guidelines and best practices, industrial processes can benefit from improved efficiency, reduced waste, and enhanced system performance. Automatic needle valves are an essential tool for achieving precise flow control and maintaining optimal operation in a wide range of applications.