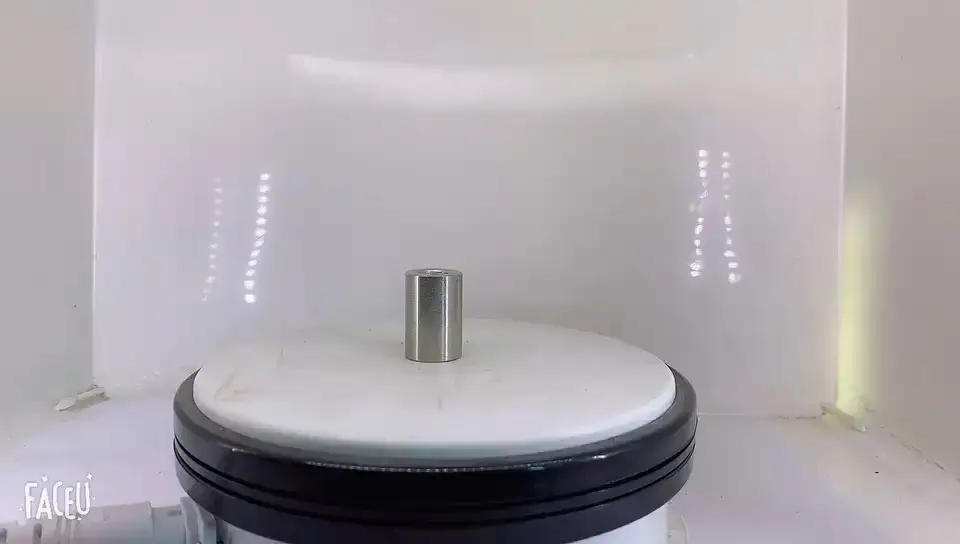

HY Carbon Steel ASTM A105 Forged Steel 3000lb Galvanized Female Thread Coupling

Detalhes do produto

Product material advantages

1. ASTM A105 forged carbon steel:

● ASTM A105 is one of the most commonly used carbon steel grades for forged pipe parts. It is often used for forged flanges and fittings for small diameter pipes. This material is suitable for pressure systems at ambient and higher temperatures.

● In terms of composition, the carbon content can reach up to 0.35%, the manganese content is 0.60 - 1.05%, the impurity content such as phosphorus and sulfur is strictly controlled (phosphorus ≤ 0.035%, sulfur ≤ 0.040%), and it also contains an appropriate amount of silicon (0.10 - 0.35%) and other elements. This combination of ingredients gives the material good comprehensive properties.

● Through a strict forging process, starting from a bar or ingot, it is cut into the required length and then forged. During the forging process, the internal structure of the material is optimized, giving it higher strength. After testing, its minimum tensile strength can reach 485MPa (70ksi), and its minimum yield strength is 250MPa (36ksi), which ensures safety and reliability when subjected to high pressure in the pipeline system.

2. Galvanizing:

● Galvanizing the forged carbon steel joints greatly improves the corrosion resistance of the product. The galvanized layer is like a solid protective armor for the product, which effectively resists the erosion of corrosive substances such as water vapor, acid and alkali in the external environment and prolongs the service life of the product.

● The galvanizing process is uniform and firm. In complex industrial environments, it can maintain good protection for a long time, reduce leakage caused by corrosion, and reduce maintenance costs.

Características do produto

● Easy installation: No welding is required, and the threaded connection method is adopted, and the installation process is simple and fast. This not only saves installation time and cost, but also is extremely convenient for the maintenance, modification or removal of the later pipeline system. At the construction site, workers can easily operate and quickly complete the connection work, improving the progress of the project.

● Reliable connection: The forging process gives the product high strength and stability, the internal thread connection is tight and well matched, and it can maintain a stable connection state when subjected to pressure and vibration, effectively preventing the pipeline from loosening or disconnecting, and ensuring the continuity and safety of medium transmission.

● Strong versatility: The product specifications meet the general industry standards and can be matched and connected with most similar models of pipelines and pipe fittings on the market, making it convenient to use in different pipeline systems, improving the applicability and versatility of the product.

Especificações do produto

● Pressure rating: 3000 lb. This pressure rating indicates that the product can withstand high internal pressure and is suitable for industrial pipeline systems with strict pressure requirements. It ensures stable operation under high pressure without potential safety hazards such as rupture and leakage.

● Thread specifications: The female thread design complies with relevant industry standards and is convenient for quick and tight connection with pipes or other pipe fittings with external threads. The female thread has high precision and can be easily screwed in during installation, while ensuring the sealing of the connection to prevent medium leakage.

● Manufacturing standards: It is manufactured in accordance with ASME (American Society of Mechanical Engineers) standards and ANSI (American National Standards Institute) standards. From raw material procurement, production and processing to finished product inspection, every link is strictly implemented in accordance with the standards to ensure that the product quality reaches the international advanced level.

| Nominal Pipe Size (NPS) | End to End Coupling W | End to End Cap P | Outside Diametei D | Minimum Fnd wall thickcness G | Mfinimum Length of Thread | ||||

| e3000 6000 | 3000 | 6000 | 3000 | 6000 | 3000 | 6000 | B | L2 | |

| 1/8” | 32 | 19 | - | 16 | 22 | 4.8 | - | 6.4 | 6.7 |

| 1/4” | 35 | 25 | 27 | 19 | 25 | 4.8 | 6.4 | 8.1 | 10.2 |

| 3/8” | 38 | 25 | 27 | 22 | 32 | 4.8 | 6.4 | 9.1 | 10.4 |

| 1/2” | 48 | 32 | 33 | 28 | 38 | 6.4 | 7.9 | 10.9 | 13.6 |

| 3/4” | 51 | 37 | 38 | 35 | 44 | 6.4 | 7.9 | 12.7 | 13.9 |

| 1" | 60 | 41 | 43 | 44 | 57 | 9.7 | 11.2 | 14.7 | 17.3 |

| 1-1/4” | 67 | 44 | 46 | 57 | 64 | 9.7 | 11.2 | 17.0 | 18.0 |

| 1-1/2” | 79 | 44 | 48 | 64 | 76 | 11.2 | 12.7 | 17.8 | 18.4 |

| 2" | 86 | 48 | 51 | 76 | 92 | 12.7 | 15.7 | 19.0 | 19.2 |

| 2-1/2” | 92 | 60 | 64 | 92 | 108 | 15.7 | 19.0 | 23.6 | 28.9 |

| 3" | 108 | 65 | 68 | 108 | 127 | 19.0 | 22.4 | 25.9 | 30.5 |

| 4" | 121 | 68 | 75 | 140 | 159 | 22.4 | 28.4 | 27.7 | 33.0 |

GENERAL NOTES:

(a)Dimensions are in millimeters

(b) Pressure unit is in LB

FAQ